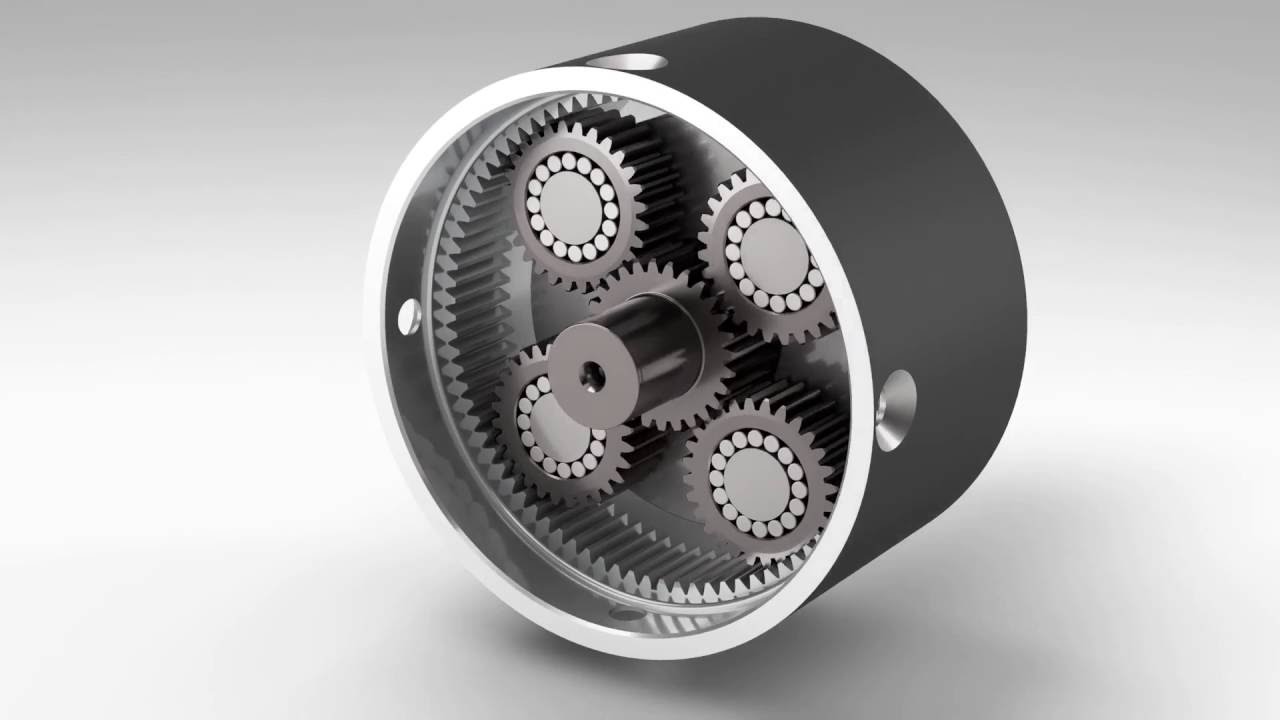

Within an epicyclic or planetary gear train, several spur gears distributed evenly around the circumference run between a gear with internal teeth and a gear with external teeth on a concentric orbit. The circulation of the spur equipment takes place in analogy to the orbiting of the planets in the solar program. This is how planetary gears acquired their name.

The elements of a planetary gear train could be divided into four main constituents.

The housing with integrated internal teeth is actually a ring gear. In nearly all cases the casing is fixed. The generating sun pinion is usually in the center of the ring gear, and is coaxially arranged with regards to the output. Sunlight pinion is usually attached to a clamping system in order to present the mechanical connection to the motor shaft. During operation, the planetary gears, which will be installed on a planetary carrier, roll between the sunshine pinion and the ring equipment. The planetary carrier as well represents the result shaft of the gearbox.

The sole purpose of the planetary gears is to transfer the mandatory torque. The number of teeth has no effect on the tranny ratio of the gearbox. The amount of planets can also vary. As the amount of planetary gears increases, the distribution of the load increases and then the torque which can be transmitted. Raising the amount of tooth engagements as well reduces the rolling electric power. Since only the main total result should be transmitted as rolling electrical power, a planetary gear is extremely efficient. The good thing about a planetary gear compared to an individual spur gear is based on this load distribution. Hence, it is possible to transmit huge torques wit

h high efficiency with a concise design using planetary gears.

Provided that the ring gear includes a frequent size, different ratios could be realized by various the amount of teeth of the sun gear and the amount of pearly whites of the planetary gears. Small the sun equipment, the greater the ratio. Technically, a meaningful ratio range for a planetary level is approx. 3:1 to 10:1, because the planetary gears and sunlight gear are extremely little above and below these ratios. Larger ratios can be acquired by connecting a number of planetary phases in series in the same band gear. In cases like this, we speak of multi-stage gearboxes.

With planetary gearboxes the speeds and torques can be overlaid by having a band gear that’s not set but is driven in any direction of rotation. Additionally it is possible to fix the drive shaft in order to grab the torque via the band gear. Planetary gearboxes have grown to be extremely important in lots of areas of mechanical engineering.

They have grown to be particularly more developed in areas where high output levels and fast speeds should be transmitted with favorable mass inertia ratio adaptation. Excessive transmission ratios can also easily be achieved with planetary gearboxes. Because of the positive properties and compact design, the gearboxes have various potential uses in industrial applications.

The features of planetary gearboxes:

Coaxial arrangement of input shaft and output shaft

Load distribution to several planetary gears

High efficiency because of low rolling power

Practically unlimited transmission ratio options because of blend of several planet stages

Appropriate as planetary switching gear because of fixing this or that portion of the gearbox

Possibility of use as overriding gearbox

Favorable volume output

Suitability for an array of applications

Epicyclic gearbox is an automatic type gearbox in which parallel shafts and gears arrangement from manual gear package are replaced with an increase of compact and more trusted sun and planetary type of gears arrangement and also the manual clutch from manual electrical power train is substituted with hydro coupled clutch or torque convertor which in turn made the transmitting automatic.

The idea of epicyclic gear box is extracted from the solar system which is known as to the perfect arrangement of objects.

The epicyclic gearbox usually includes the P N R D S (Parking, Neutral, Reverse, Drive, Sport) settings which is obtained by fixing of sun and planetary gears in line with the need of the travel.

The different parts of Epicyclic Gearbox

1. Ring gear- This is a kind of gear which looks like a ring and also have angular slice teethes at its interior surface ,and is positioned in outermost posture in en epicyclic gearbox, the interior teethes of ring equipment is in regular mesh at outer point with the group of planetary gears ,it is also known as annular ring.

2. Sun gear- It’s the equipment with angular cut teethes and is located in the center of the epicyclic gearbox; the sun gear is in constant mesh at inner level with the planetary gears and is normally connected with the type shaft of the epicyclic gear box.

One or more sunshine gears can be utilized for reaching different output.

3. Planet gears- They are small gears used in between band and sun equipment , the teethes of the earth gears are in constant mesh with sunlight and the ring equipment at both inner and outer points respectively.

The axis of the planet gears are attached to the earth carrier which is carrying the output shaft of the epicyclic gearbox.

The planet gears can rotate

4. Planet carrier- This is a carrier attached with the axis of the planet gears and is accountable for final transmitting of the outcome to the result shaft.

The earth gears rotate over the carrier and the revolution of the planetary gears causes rotation of the carrier.

5. Brake or clutch band- These devices used to fix the annular gear, sunshine gear and planetary equipment and is managed by the brake or clutch of the automobile.

Working of Epicyclic Gearbox

The working principle of the epicyclic gearbox is based on the fact the fixing any of the gears i.e. sun equipment, planetary gears and annular equipment is done to get the necessary torque or swiftness output. As fixing the above causes the variation in gear ratios from large torque to high speed. So let’s observe how these ratios are obtained

First gear ratio

This provide high torque ratios to the automobile which helps the automobile to move from its initial state and is obtained by fixing the annular gear which in turn causes the planet carrier to rotate with the power supplied to sunlight gear.

Second gear ratio

This provides high speed ratios to the vehicle which helps the automobile to achieve higher speed during a travel, these ratios are obtained by fixing sunlight gear which in turn makes the earth carrier the motivated member and annular the traveling member so that you can achieve high speed ratios.

Reverse gear ratio

This gear reverses the direction of the output shaft which in turn reverses the direction of the automobile, this gear is attained by fixing the planet gear carrier which makes the annular gear the driven member and the sun gear the driver member.

Note- More rate or torque ratios can be achieved by increasing the quantity planet and sun gear in epicyclic gear container.

High-speed epicyclic gears could be built relatively little as the energy is distributed over several meshes. This outcomes in a low capacity to excess weight ratio and, as well as lower pitch line velocity, leads to improved efficiency. The tiny equipment diameters produce lower moments of inertia, significantly minimizing acceleration and deceleration torque when beginning and braking.

The coaxial design permits smaller and for that reason more cost-effective foundations, enabling building costs to be kept low or entire generator sets to be integrated in containers.

Why epicyclic gearing is utilized have been covered in this magazine, so we’ll expand on the topic in only a few places. Let’s commence by examining a crucial aspect of any project: cost. Epicyclic gearing is normally less expensive, when tooled properly. Just as one would not consider making a 100-piece lot of gears on an N/C milling equipment with a form cutter or ball end mill, you need to not consider making a 100-piece large amount of epicyclic carriers on an N/C mill. To preserve carriers within affordable manufacturing costs they should be created from castings and tooled on single-purpose machines with multiple cutters concurrently removing material.

Size is another component. Epicyclic gear models are used because they are smaller than offset equipment sets since the load is shared among the planed gears. This makes them lighter and smaller sized, versus countershaft gearboxes. As well, when configured effectively, epicyclic gear units are more efficient. The next example illustrates these benefits. Let’s believe that we’re developing a high-speed gearbox to gratify the following requirements:

• A turbine provides 6,000 horsepower at 16,000 RPM to the insight shaft.

• The outcome from the gearbox must drive a generator at 900 RPM.

• The design your life is usually to be 10,000 hours.

With these requirements at heart, let’s look at three practical solutions, one involving an individual branch, two-stage helical gear set. A second solution takes the original gear collection and splits the two-stage lowering into two branches, and the 3rd calls for by using a two-stage planetary or star epicyclic. In this situation, we chose the superstar. Let’s examine each one of these in greater detail, seeking at their ratios and resulting weights.

The first solution-a single branch, two-stage helical gear set-has two identical ratios, derived from taking the square root of the final ratio (7.70). Along the way of reviewing this option we recognize its size and pounds is very large. To reduce the weight we after that explore the possibility of making two branches of a similar arrangement, as observed in the second alternatives. This cuts tooth loading and decreases both size and excess weight considerably . We finally reach our third option, which may be the two-stage celebrity epicyclic. With three planets this equipment train decreases tooth loading significantly from the primary approach, and a relatively smaller amount from remedy two (look at “methodology” at end, and Figure 6).

The unique style characteristics of epicyclic gears are a big part of why is them so useful, but these very characteristics could make creating them a challenge. In the next sections we’ll explore relative speeds, torque splits, and meshing considerations. Our target is to make it easy that you should understand and use epicyclic gearing’s unique design characteristics.

Relative Speeds

Let’s get started by looking at how relative speeds job together with different plans. In the star set up the carrier is fixed, and the relative speeds of sunlight, planet, and band are simply determined by the speed of 1 member and the number of teeth in each gear.

In a planetary arrangement the ring gear is fixed, and planets orbit sunlight while rotating on earth shaft. In this arrangement the relative speeds of the sun and planets are determined by the quantity of teeth in each gear and the quickness of the carrier.

Things get a bit trickier whenever using coupled epicyclic gears, since relative speeds might not exactly be intuitive. It is therefore imperative to often calculate the velocity of sunlight, planet, and ring in accordance with the carrier. Understand that possibly in a solar set up where the sunlight is fixed it has a speed marriage with the planet-it is not zero RPM at the mesh.

Torque Splits

When contemplating torque splits one assumes the torque to be divided among the planets equally, but this may well not be considered a valid assumption. Member support and the amount of planets determine the torque split represented by an “effective” amount of planets. This number in epicyclic sets designed with two or three planets is in most cases equal to using the amount of planets. When more than three planets are employed, however, the effective amount of planets is always less than the actual number of planets.

Let’s look by torque splits regarding set support and floating support of the people. With set support, all people are backed in bearings. The centers of sunlight, ring, and carrier will never be coincident because of manufacturing tolerances. For this reason fewer planets are simultaneously in mesh, producing a lower effective amount of planets posting the load. With floating support, one or two people are allowed a tiny amount of radial independence or float, which allows the sun, ring, and carrier to get a posture where their centers happen to be coincident. This float could be as little as .001-.002 ins. With floating support three planets will be in mesh, producing a higher effective number of planets posting the load.

Multiple Mesh Considerations

At the moment let’s explore the multiple mesh considerations that needs to be made when making epicyclic gears. 1st we should translate RPM into mesh velocities and determine the number of load application cycles per unit of time for each member. The first step in this determination is certainly to calculate the speeds of every of the members in accordance with the carrier. For instance, if the sun equipment is rotating at +1700 RPM and the carrier is rotating at +400 RPM the speed of the sun gear relative to the carrier is +1300 RPM, and the speeds of world and ring gears could be calculated by that acceleration and the numbers of teeth in each of the gears. The use of indications to signify clockwise and counter-clockwise rotation is important here. If the sun is rotating at +1700 RPM (clockwise) and the carrier is rotating -400 RPM (counter-clockwise), the relative acceleration between the two customers is usually +1700-(-400), or +2100 RPM.

The next step is to identify the number of load application cycles. Because the sun and band gears mesh with multiple planets, the number of load cycles per revolution in accordance with the carrier will be equal to the quantity of planets. The planets, even so, will experience only one bi-directional load request per relative revolution. It meshes with the sun and ring, but the load is definitely on reverse sides of one’s teeth, resulting in one fully reversed anxiety cycle. Thus the earth is considered an idler, and the allowable anxiety must be reduced 30 percent from the value for a unidirectional load app.

As noted over, the torque on the epicyclic associates is divided among the planets. In analyzing the stress and life of the associates we must consider the resultant loading at each mesh. We find the idea of torque per mesh to end up being relatively confusing in epicyclic equipment evaluation and prefer to look at the tangential load at each mesh. For example, in searching at the tangential load at the sun-world mesh, we have the torque on the sun gear and divide it by the powerful number of planets and the operating pitch radius. This tangential load, combined with the peripheral speed, is utilized to compute the energy transmitted at each mesh and, modified by the strain cycles per revolution, the life expectancy of every component.

Furthermore to these issues there may also be assembly complications that need addressing. For example, positioning one planet in a position between sun and ring fixes the angular situation of sunlight to the ring. The next planet(s) is now able to be assembled only in discreet locations where the sun and band could be at the same time engaged. The “least mesh angle” from the primary planet that will accommodate simultaneous mesh of another planet is equal to 360° divided by the sum of the amounts of teeth in the sun and the ring. Therefore, to be able to assemble further planets, they must become spaced at multiples of the least mesh position. If one wants to have equivalent spacing of the planets in a straightforward epicyclic set, planets may be spaced equally when the sum of the amount of teeth in sunlight and band is normally divisible by the number of planets to an integer. The same rules apply in a substance epicyclic, but the set coupling of the planets brings another degree of complexity, and proper planet spacing may require match marking of pearly whites.

With multiple elements in mesh, losses must be considered at each mesh so as to evaluate the efficiency of the machine. Electrical power transmitted at each mesh, not input power, must be used to compute power reduction. For simple epicyclic pieces, the total electric power transmitted through the sun-planet mesh and ring-world mesh may be significantly less than input electricity. This is one of the reasons that easy planetary epicyclic units are more efficient than other reducer plans. In contrast, for most coupled epicyclic units total ability transmitted internally through each mesh could be greater than input power.

What of ability at the mesh? For straightforward and compound epicyclic models, calculate pitch range velocities and tangential loads to compute electrical power at each mesh. Values can be acquired from the planet torque relative velocity, and the functioning pitch diameters with sun and band. Coupled epicyclic sets present more technical issues. Components of two epicyclic models could be coupled 36 different ways using one type, one outcome, and one reaction. Some plans split the power, while some recirculate electrical power internally. For these types of epicyclic units, tangential loads at each mesh can only just be established through the usage of free-body diagrams. Additionally, the elements of two epicyclic models can be coupled nine various ways in a series, using one source, one productivity, and two reactions. Let’s look at some examples.

In the “split-electricity” coupled set demonstrated in Figure 7, 85 percent of the transmitted vitality flows to band gear #1 and 15 percent to band gear #2. The effect is that coupled gear set could be more compact than series coupled models because the electrical power is split between your two components. When coupling epicyclic models in a string, 0 percent of the energy will end up being transmitted through each arranged.

Our next case in point depicts a established with “power recirculation.” This equipment set happens when torque gets locked in the system in a way similar to what takes place in a “four-square” test procedure for vehicle drive axles. With the torque locked in the machine, the hp at each mesh within the loop improves as speed increases. As a result, this set will knowledge much higher electric power losses at each mesh, leading to drastically lower unit efficiency .

Physique 9 depicts a free-body diagram of a great epicyclic arrangement that activities electricity recirculation. A cursory analysis of this free-body system diagram clarifies the 60 percent productivity of the recirculating set shown in Figure 8. Since the planets happen to be rigidly coupled collectively, the summation of forces on the two gears must the same zero. The power at sunlight gear mesh benefits from the torque insight to the sun gear. The power at the next ring gear mesh effects from the result torque on the band equipment. The ratio being 41.1:1, result torque is 41.1 times input torque. Adjusting for a pitch radius big difference of, say, 3:1, the power on the second planet will be about 14 times the force on the first planet at the sun gear mesh. Consequently, for the summation of forces to mean zero, the tangential load at the first band gear should be approximately 13 moments the tangential load at sunlight gear. If we believe the pitch line velocities to be the same at the sun mesh and ring mesh, the energy loss at the band mesh will be roughly 13 times higher than the power loss at the sun mesh .

epicyclic gearbox

TAGs: